How Businesses Can Protect Against Covid-19

This is an unprecedented experience in modern day that we are living through. Covid-19, also known as the coronavirus, is ravaging its way around our world and is upending life as we know it. Most people are in isolation or quarantine; and the business world has been interrupted on a scale that many of us have never seen in our lifetimes. Now more than ever; is the time to be armed with information on how to protect yourself and your business during this time of global outbreak.

Preparing Workplaces for a COVID-19 Outbreak

Businesses and employers can prevent and slow the spread of COVID-19 by being prepared and reacting accordingly. You should plan to respond to varying levels of disease transmission in your community in a flexible way. Be prepared to constantly refine your daily business model matching the demands of the outbreak.

According to the Occupational Safety and Health Administration (OSHA), most American workers will likely experience low- to medium-exposure risk levels at their job or place of employment, regardless of the industry. All employers need to consider how best to decrease the spread of COVID-19 and lower the impact in their workplace.

Reduce Transmission Among Employees

One of the most proactive and effective strategies for fighting the virus is to try and reduce the transmission between your employees. While it might be hard on your bottom line, it is imperative that you actively encourage any sick employees to work from home, even if they don’t have symptoms related to coronavirus.

Employees who show any symptoms of coronavirus should immediately notify their supervisor and remain at home. Sick employees should not return to work until they have met the criteria to stop isolating at home, usually after being tested and cleared by a medical professional. It is even advised that if an employee has a sick family member in their household that they notify their supervisor and make plans to work from home if possible.

If one of your employees begins to display symptoms (i.e., fever, cough, or shortness of breath) upon arrival at work or who become sick during the day should immediately be separated from other employees and sent home. If an employee is confirmed to have coronavirus, you need to inform fellow employees of their possible exposure to COVID-19 in the workplace, while maintaining confidentiality as required by the Americans with Disabilities Act (ADA).

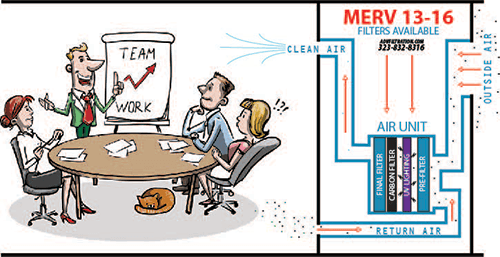

It is important to be aware that some employees may be at higher risk for serious illness, such as older adults and those with chronic medical conditions such as obesity and diabetes. Consider minimizing face-to-face contact between these employees or assign work tasks that allow them to maintain a distance of six feet from other workers, customers and visitors, or to telework if possible. Video conferencing has never been a more important workplace tool as it is nowadays.

Maintain Healthy Business Operations

During this time of crisis, it is crucial to educate employees about how they can reduce the spread of COVID-19 in your workplace. One ingenious practice some businesses have begun is to appoint a workplace coordinator who is responsible for COVID-19 related issues and their impact at the workplace. Their job would be to inform employees of proper hand cleanliness procedures such as:

- Wash your hands often with soap and water for at least 20 seconds. Use hand sanitizer with at least 60% alcohol if soap and water are not available.

- Avoid touching your eyes, nose, and mouth with unwashed hands.

- Cover your mouth and nose with a tissue when you cough or sneeze or use the inside of your elbow. Throw used tissues in the trash and immediately wash hands with soap and water for at least 20 seconds.

- Clean and disinfect frequently touched objects and surfaces such as workstations, keyboards, telephones, handrails, and doorknobs. Dirty surfaces can be cleaned with soap and water prior to disinfection. To disinfect, use products that meet the Environmental Protection Agency’s (EPA) criteria for use against COVID-19, and are appropriate for the surface.

- Avoid using other employees’ phones, desks, offices, or other work tools and equipment, when possible. If necessary, clean and disinfect them before and after use.

- Practice social distancing by avoiding large gatherings and maintaining distance (approximately 6 feet or 2 meters) from others when possible.

Maintain a Healthy Work Environment

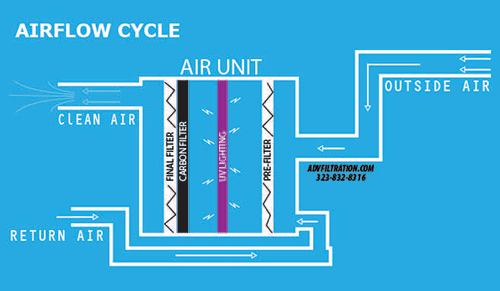

One of the more overlooked and technical areas of safety improvement you can focus on for your business is the airflow ventilation system. This particular virus is one that attacks the respiratory system, so it is now more important than ever to have a high functioning commercial air filtration system.

Consider improving the building ventilation system by increasing ventilation rates or increasing the percentage of outdoor air that circulates into the system. You can also look into upgrading your system’s industrial air filters to something like the HVP Hepa Filter from Engineered Filtration Systems (EFS). These filters work overtime in preventing the spread of this deadly disease.

Along with upgrading your air ventilation system, support respiratory etiquette and hand hygiene for employees, customers, and worksite visitors. You can do this by providing tissues and no-touch disposal receptacles in all common areas. Make sure your restroom facilities offer soap and clean water. If soap and water are not readily available, use alcohol-based hand sanitizer that is at least 60% alcohol. If hands are visibly dirty, soap and water should be chosen over hand sanitizer. Ensure that adequate supplies are maintained. Place hand sanitizers in common areas to encourage hand hygiene. You can also place posters that encourage hand hygiene to help stop the spread at the entrance to your workplace and in other workplace areas where they are likely to be seen. While it is commonplace in the business world to shake hands, it is best to discourage handshaking.

Lastly, it is ideal to perform routine environmental cleaning and disinfection. Routinely clean and disinfect all frequently touched surfaces in the workplace, such as workstations, keyboards, telephones, handrails, and doorknobs. If surfaces are dirty, they should be cleaned using a detergent or soap and water prior to disinfection.

For disinfection, most common EPA-registered household disinfectants should be effective. Provide disposable wipes so that commonly used surfaces (for example, doorknobs, keyboards, remote controls, desks, other work tools and equipment) can be wiped down by employees before each use.

Armed with this information, you can protect your employees, your business and do your part in preventing the further spread of the coronavirus.

Call EFS for more information about the best commercial air filters to use for your company’s ventilation system.