The air filtration industry has seen quite a bit of change over the last decade. Manufacturers have created new products, such as higher quality and functioning air filters, that not only have improved indoor air quality (IAQ), but also have reduced installation and operation costs of air-filtration equipment in commercial facilities.

Along with technology improvements, industry organizations are adopting standards, guidelines and requirements that promote healthy indoor air quality. These organizations are continually learning about the impact indoor air quality can have on building occupants, including productivity and overall occupant health as air quality improves.

As engineering and maintenance managers continue to focus on indoor air quality and its impact on their facilities and occupants, manufacturers such as EFS are providing them with more efficient HVAC systems and components, including air filters. These technological advances include reduced pressure drops and overall improved filter efficiency throughout the HVAC system.

Organizing Bodies & Standards

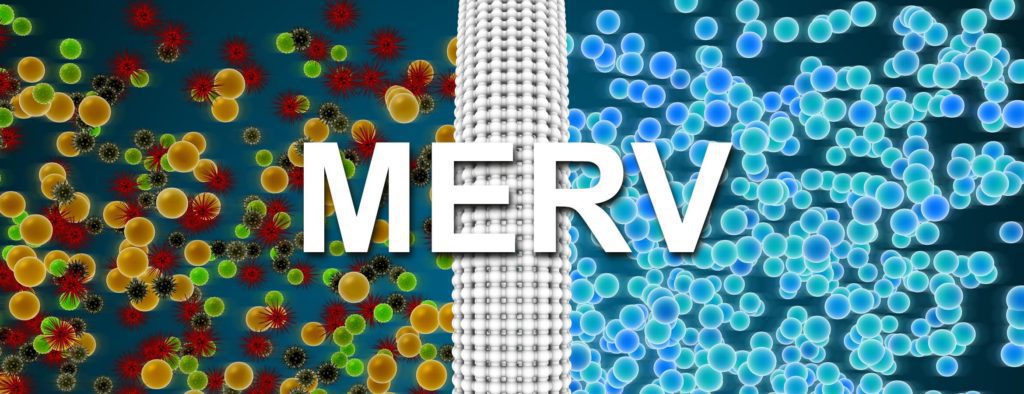

When the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) introduced indoor air quality standards, it signaled an important and necessary change in the air-filtration industry. ASHRAE has been aggressively promoting the adoption and use of the minimum efficiency reporting value (MERV) system to standardize definitions of efficiencies. When selecting an air filter for your business, avoid manufacturers who have not adopted the MERV system.

In layman’s terms, MERV measures a filter’s arrestance, which is defined as a filter’s ability to remove large airborne particles from the air. Next it measures dust-spot efficiency, or a filter’s ability to remove small airborne particles. The MERV system then takes these two factors into account and assigns a number based on the filter’s ability to remove the particles. Several types of air filters are common in commercial HVAC systems.

Types of HVAC Filters

There are four common types of air filters that you will find for sale for your HVAC system.

Fiberglass filters: Layered fiberglass fibers are laid over each other to form the filter media and typically are reinforced with a metal grating that supports the fiberglass to prevent failure and collapse. Because of their metal grating they are prone to rips and tears in the media. These filters are very common and meant to be thrown out when they have served their purpose, not replaced or cleaned.

Polyester and pleated filters: These filters are similar to fiberglass filters but typically have a higher resistance to airflow and a superior dust-stopping ability. These filters are often housed in sturdy plastic that prevent tearing and rips to the non-shedding media. These filters, such as the EFS V-Bank filter are a very popular choice for today’s modern industrial filtration needs.

High efficiency particulate arrestance (HEPA) filters: These units filter the air passing through them at a very fine scale. The U.S. Department of Energy (DOE) and its contractors use HEPA filters that meet DOE standard STD-3020-97, Specification for HEPA Filters Used by DOE Contractors, to filter 99.97 percent of all particles 0.3 microns or larger. These would be found in very high-end electronic factories or medical buildings.

Washable air filters: These products are not as common and rely on the build-up of dust along the cloth to improve the efficiency of the filter. Industrial processes involving high volumes of coarse dust are typical applications. These are not recommended for medical buildings or places with high volumes of occupants as they are more prone to biofilm build up and spreading harmful materials through the air.

EFS High Efficiency V-Bank Filters

A V-Bank filter is what we call a mini-pleated filter; it’s a high-efficiency filter with a higher media area than a standard box filter. The standard size is still 24 x 24 x 12, like the box filter, but there’s a big difference between the mini-pleated V-Bank filter and a box filter: most box filters have a metal frame and don’t have a large amount of filtration media. The actual pleat packs, which is what the media is manufactured into, are installed into the V-Bank filter in a ‘V’ shape – hence the term V-Bank. The majority of ours are 4 V’s.

High efficiency V-bank filters from EFS offer high efficiency, low-pressure drop, long filter life, and filter media that resists moisture. These filters are designed to tolerate high velocities and turbulence, making them suitable for many types of air handling systems. The synthetic filter contains no metal parts, eliminating the risk of corrosion. EFS high efficiency synthetic V-bank filters are made of lightweight plastic for easy handling and transportation. The high-quality build gives our filters longer performance life, which reduces maintenance and replacement costs.

The frames of those V-Banks are plastic, and though the majority of EFS V-Bank filters have both synthetic and a glass-laid media available, we see much more use for the synthetic media as it does not respond to moisture, which is important due to our work in high-humidity areas. Hospitals, gas turbine power plants, clean rooms, universities, data centers, airports, hotels, micro-electronics or pharmaceutical manufacturers, and pretty much any application that has a true air handler could use a V-Bank filter as their final filter.

It is especially crucial in hospitals and cleanrooms to maintain a sterile environment and remain confident that airborne diseases or toxins are being filtered correctly and efficiently. Making the V- Bank filter the perfect fit using its high efficiency, low-pressure drop, long filter life and synthetic filter media that resists moisture. They are also designed to withstand high velocities and turbulence making them durable in most air handling systems. In any case, the V-Bank filter possesses very few cons in its application for air handling units.

Patented 1” recess design for “V” style filters drastically lowers pressure drop when used in conjunction with pleated or panel style pre-filters on the face of the filter. The patented 1” recess provides full utilization of the entire pre-filter media area.

V-Bank filters have been developed specifically for intake, exhaust, and recirculated air filtration HVAC systems that have stringent requirements for clean air quality and cost efficiency. The MV85 V-Banks are potted into a high strength all plastic frame. This assures the user of maximum operational dependability and consistent filtration throughout each specific application. The sturdy construction assures optimum performance under turbulent flow conditions and load changes. This means that the risk of particle or fiber shedding is practically eliminated. The media is resistant to physical damage from moisture and chemicals.

When selecting your next HVAC air filter, look no further than the EFS High Efficiency V-Bank Filters.