It’s important to keep your gas turbine air inlet in tip top shape. It helps to prevent degradation of your filters and prevents further deterioration of your inlet. Investing in gas turbine air inlet refurbishment services increases the lifecycle of your inlet air intake. It will require less overall maintenance and increase the efficiencies of your cooling section.

Replacing Gas Turbine Inlet Air Filters

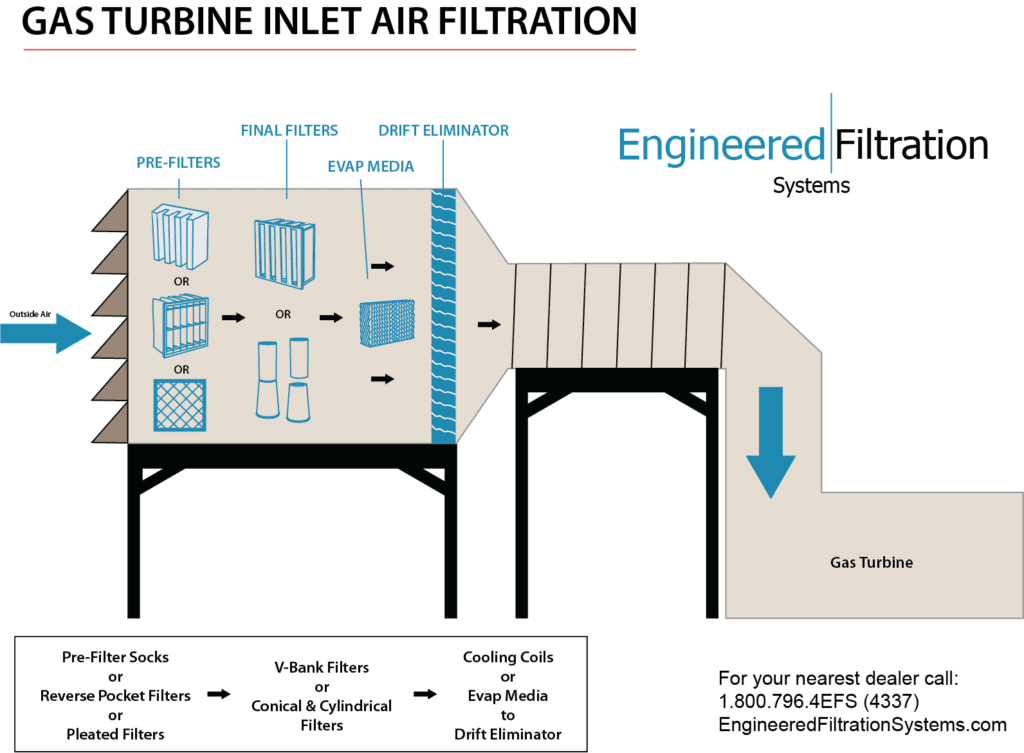

At Engineered Filtration Systems, we offer many solutions for gas turbine filter replacements. From pre-filters to final filters, as well as, evaporative media and drift eliminators. We are your go to filter company for Gas Turbine inlet air filters and gas turbine fluid filters. Having the correct filters in place is crucial for the efficiency of your gas turbine air inlet. Filters lose efficiency overtime and clogged filters can put a lot of strain on your machines. It’s important to replace your filters when needed to increase production.

Gas Turbine Air Inlet Refurbishment

Another step you can take to keep your GT air inlet running as efficient as possible is to look into refurbishment services. Advanced Filtration Concepts has a team that can offer full turnkey GT air inlet refurbishment services. They do a full removal of the pre-filter wall, all filters and other components. Then ice blast, recoat and re-install everything, including new filters. To learn about the whole process and everything they can offer, please contact AFC. From Air inlet to catalyst, the deep cleaning process can save you on costs and downtime.

Conclusion

Ongoing maintenance is important for any system. You need to have your machines working at all times and here’s no room for downtime. Keep your gas turbine air inlet clean and efficient by replacing your filters in a timely manner or when needed. Don’t let your GT inlets get to the point of needing to be replaced. For any questions, please contact us anytime.

Would you be interested in a sensor to monitor clogging of the (GLASdek or CELdek) cooling media?